Learning

The "r" in rPET stands for "recycled." While virgin PET plastic is derived from petroleum and petrochemicals, it can be recycled into rPET—a material that conserves natural resources.

An industry study conducted by ALPLA revealed that producing rPET generates fewer carbon emissions compared to virgin PET. According to ALPLA's PET Recycling Team, the carbon footprint of rPET is 0.45 kg CO₂ equivalent per kilogram, whereas virgin PET accounts for 2.15 kg CO₂ equivalent per kilogram. These findings are consistent with a 2019 report released by the Association of Plastic Recyclers.

rPET is a more sustainable alternative, and technically, it can replace PET in any application. Numerous studies also indicate that plastic generally has a lower carbon footprint than traditional materials such as glass, aluminum, and paper.

Advantages of Our rPET Dinnerware:

Our Factory’s Strengths:

Our factory is developing an integrated industrial chain—from PET recycling to rPET product manufacturing. Key processes include:

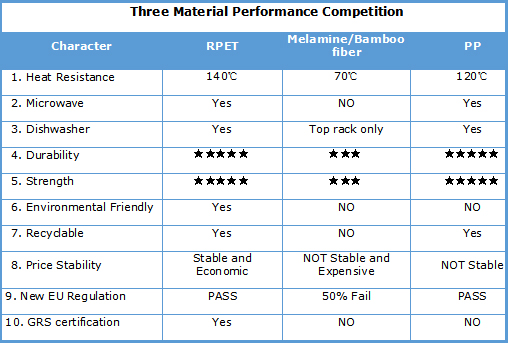

Comparison with PP:

Comparison with Melamine:

Environmental Impact of rPET:

Recycling PET bottles not only diverts waste from landfills but also creates valuable raw material for new products. Using recycled PET resin significantly lowers greenhouse gas emissions, reduces carbon footprint, and requires less energy compared to producing items from virgin materials or landfilling.